Printable Tap Drill Chart: Your Essential Guide to Precision Drilling

Step into the world of precision drilling with our comprehensive guide to printable tap drill charts. These invaluable tools are the secret to achieving perfectly sized holes for seamless tapping, ensuring the integrity and longevity of your projects.

Dive into the intricate world of tap drill charts, where we’ll decipher the symbols, understand the conventions, and explore their applications across diverse industries. From selecting the optimal drill size for various materials to advanced techniques for accuracy, this guide will empower you with the knowledge to master the art of drilling and tapping.

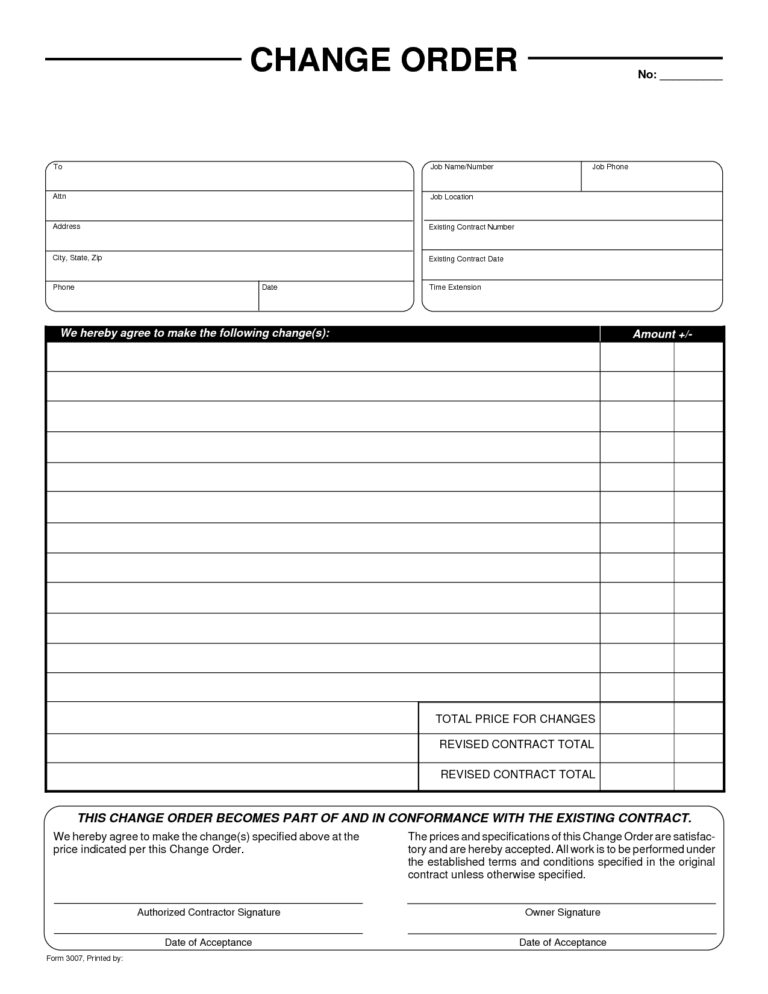

Printable Tap Drill Chart

Innit, you want a Tap Drill Chart you can print off, blud? Well, look no further, cuz we got you sorted. This chart’s got all the info you need to drill holes for taps, so you can get your DIY projects sorted without any aggro.

This chart is easy peasy to use. Just find the size of the tap you’re using in the left-hand column, and then read across to find the right drill size. It’s that simple, mate.

So, whether you’re a seasoned pro or a complete newbie, this Tap Drill Chart is the perfect tool for you. Print it off and keep it handy in your workshop, and you’ll never have to guess what drill size to use again.

Drill Size Chart

| Tap Size | Drill Size |

|---|---|

| M1 | 0.8mm |

| M1.2 | 1mm |

| M1.4 | 1.2mm |

| M1.6 | 1.4mm |

| M1.8 | 1.6mm |

| M2 | 1.8mm |

| M2.2 | 2mm |

| M2.5 | 2.2mm |

| M3 | 2.5mm |

| M3.5 | 2.8mm |

| M4 | 3.2mm |

| M4.5 | 3.5mm |

| M5 | 4mm |

| M5.5 | 4.5mm |

| M6 | 5mm |

| M7 | 5.5mm |

| M8 | 6mm |

| M9 | 6.5mm |

| M10 | 7mm |

| M11 | 7.5mm |

| M12 | 8mm |

There you have it, mate. Your very own Printable Tap Drill Chart. Now you can get drilling those holes like a pro.

Common Queries

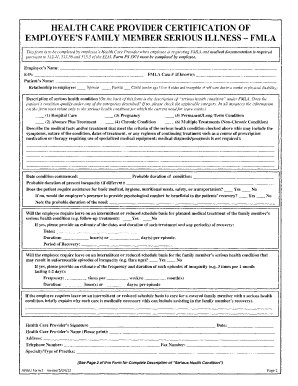

What materials are suitable for tapping?

A wide range of materials can be tapped, including metals (steel, aluminum, brass), plastics, and even wood. The chart provides specific drill size recommendations for each material type.

How do I select the appropriate drill size?

The chart lists recommended drill sizes for various tap sizes and materials. Consider factors such as the material’s hardness, thread pitch, and desired tolerance range when making your selection.

What are the potential consequences of using incorrect drill sizes?

Incorrect drill sizes can lead to stripped threads, weakened joints, or even snapped taps. Using the correct drill size ensures a secure and durable connection.

How do I maintain and update my tap drill chart?

Over time, tool wear and material properties can affect the accuracy of the chart. Regularly check and update the chart based on your observations and experience.